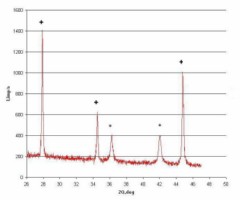

X-ray Phase Analysis and X-ray Structure Analysis of Powders

. phase composition; X-ray phase and structure analyses are carried out on the “DRON 4M” X-ray diffractometer manufactured by Burevestnik, Russia, СuK?, FeK?, CoK? radiation, Johansson-type monochromator for structural analysis. The technique is certified to meet the requirements of the Government Standard R ISO/MEK 17025 according to the Analytical Laboratory Accreditation System (2009-2011). X-ray phase analysis It is often necessary to perform initial and final control of the main and impurity phase composition of powder materials as well as analysis to confirm that requirements of the State Standard and Technical Specifications are met. During the treatment of powders it is necessary to monitor the possible phase composition changes: occurrence of oxidation, formation of intermetallic phases or polymorphic transformation products. The formation of by-products can change physico-chemical characteristics of milled powders. The method of internal standard reference and the “ANALIZER” program are used for the quantitative phase analysis. Crystallite size determination Changes in broadening of diffraction maxima, maxima displacement, and changes of X-ray lines intensity can be used for characterization of nanostructuring of powders and presence of defects [Streletskiy A.N., Lapshin V.I., Fokina E.L., 1989. Kinetics and Catalysis. 30, 1064-1069]. X-ray structure analysis allows one to determine crystallite size which is called “the size of regions of coherent scattering” in Russian literature. Determination of the degree of coverage of the surface of dielectric particles with metal The technique for determination of the degree of coverage of the surface of dielectric particles (ceramic, diamond) with metals was developed with the participation of the company employees. The specific feature of the technique is the possibility to measure properties of the near-surface layers of different depth. The depth of penetration depends on the composition of the analyzed sample. Result is achieved due to the special exposure conditions, beam focusing, and specimen adjustment. During the exposure in these conditions it is possible to analyze the sample both at different depths and in a microdiffraction mode.

|

Active-nano (Andrey V. Petrov)

. Crystallite size is calculated on the basis of changes of all parameters listed above. If the powder particles consist of crystallites (grains) of the size less than 100 nm, these particles can be referred to as nanostructured particles.

. Crystallite size is calculated on the basis of changes of all parameters listed above. If the powder particles consist of crystallites (grains) of the size less than 100 nm, these particles can be referred to as nanostructured particles.