Determination of the Particle Specific Surface Area

Determination of the Particle Specific Surface Area The specific surface area of particles influences the powder behaviour during moulding and sintering. This characteristic is also important in such processes as heterogeneous catalysis, adsorption, and reactions running on a surface. The powder specific surface is a sum of outer surfaces of all the particles present in unit volume or mass. It depends upon the particles shape, size and microstructure. The fine powder typically has the specific surface area value in the range from units to tens m2/g.

To measure the powder specific surface area we use the gas adsorption method. Gas-chromatographic definition of the powder specific surface area is carried out using argon thermodesorption method. Dynamic gas-chromatographic method differs from static adsorption methods by its high selectivity. It is relatively fast and provides a wide range of measurments of specific surface area values: from 0,01 m2/g до 1000 m2/g.

The powders’ specific surface area is calculated from the BET equation (BET comes from initial letters in authors' names as it was proposed by Brunauer, Emmett, and Teller) basing on the specific retention volumes which are determined from the gas chromatogrammes of heat desorption. Argon is used as an adsorbate while helium is used as a carrier gas. The relative error of the specific surface area determination doesn’t exceed 10%.

If we know the specific weight () of the powder material, determine the powder specific surface (SSA), and suppose that particles have spherical shape, we can estimate their average diameter by the formula: D = 6 / (SSA* ρ).

However it should be taken into account that such estimation is based on two assumptions: (i) particles are spherical; (ii) porosity is absent. Thus, in many cases the method can underestimate the particle average size.

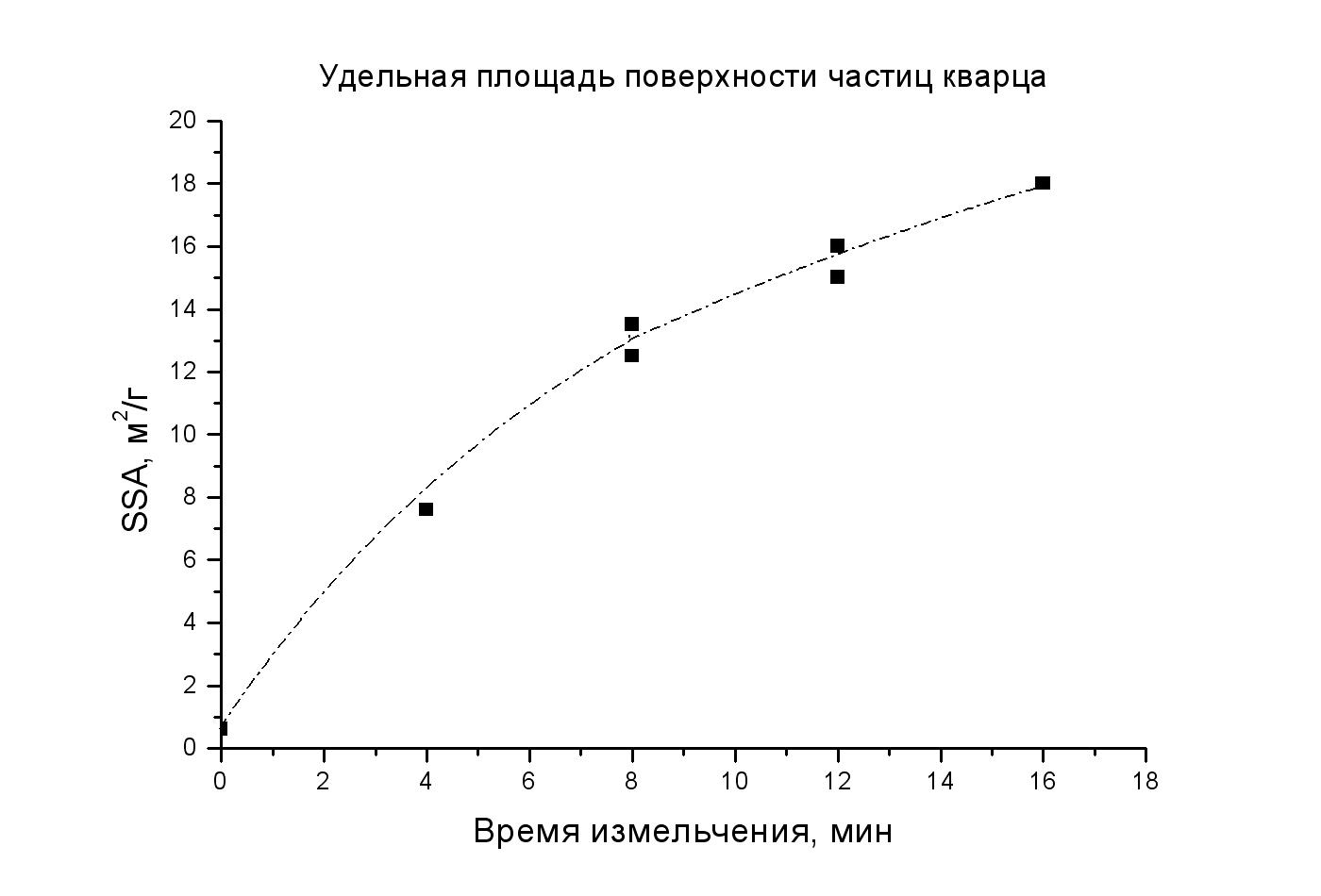

Example. The results of the silica (SiO2) particles specific surface area measurement. Milling of silica was carried out in a planetary mill MPP-1.

| Milling time, min |

Specific surface area, m2/g |

| 0 |

0.6 |

| 4 |

7.6 |

| 8 |

12.5

13.5

|

| 12 |

15

16

|

| 16 |

18 |

|

|

Specific surface area increased thirtyfold as a result of milling in a planetary mill for 16 minutes. The average particle diameter calculated for ρ =2.65 g/cm3 and specific surface area SSA = 18 m2/g is 126 nm.

|